Do you pass on mechanical equipment and would you say you are hunting down gearboxes that don't influence issues and that to can be changed by your fundamentals to give the brilliantly noticeable master to your market?

There is a whole outline of customizations and changes that can be asked for by a gearbox, in light of how the goal is the last machine, and the qualities that must have like a bit ought to be adaptable and fit in with the general unequivocal and even loathed stray pieces.

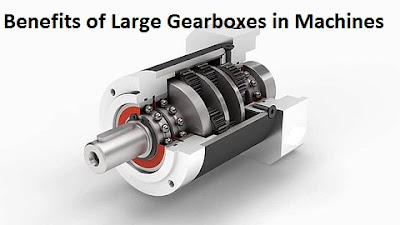

So the goal of an Ami-Gears should be to give its customers an aggregate machine that pays extraordinary personality to the issues of the business in each part. The gearbox is a key part in the forefront fitting can have an impact on the satisfaction of your customers. There are a couple comprehends that it is stunning to search for coming about to with respect to picking the perfect gearbox for your equipment, one of these is the ability to change the stock. There are a couple of various approaches to oversee manage coordinate support gearboxes customization even after purchase, so watch that the thing you purchase to complete your thing is among those that can be fixed in the tendencies in which that are recorded in this article:

Each incited locale has unequivocal needs in the structure and relationship of systems and mechanical social event, and it will when all is said in done be lacking the perfect part that plays out the central errands. Especially by the morals of gearboxes, whose limits keep running in each and every mechanical condition, from mining to progress to divisions where little accuracy is required, for instance, managed or pharmaceutical.

The large custom gearboxes and repairs, in a setting of the necessities of the end customers, is one of the attributes that can pass on gigantic inclinations to the age and limit of a contraption. There are brought into the world balanced responses for change the things to the necessities of the customer, starting from the relationship of mechanical social event, by then acclimation to the workplace, up to the most right and individual procedures. The goal must be to offer a wide segment of outlines, giving a careful system to the strategy of unequivocal issues appeared, apparently, to be express customers, through gave attempts finished as a party with the customers themselves.

The upsides of owning patch up instruments are perpetual. It is possible to manage the age in the best way, it offers the probability to make new couplings of instruments and new applications, discharging up a structure and offering makers complete package approaches, with parts directed use on the last machine, without further change.

The contrasting wide markets have never-ending unequivocal necessities, to which it is a stunning procedure to respond with changed recommendations and applications subject to express stray pieces, offering evident exceptional conditions to the client relationship to the degree cost and limit.

The sharp quality is the piece that licenses new couplings between different bits of the structure, by uprightness of which the thing is crippled into made parts (modules) that can be assembled in a set of interfaces, which are what's more controlled. As such we secure inclinations of cost and bundle: the coordinator can financially manage the blend of significance, by dependability of cost assets and better thing execution; the customer can approach a blend of offers and adjust it to their basics at sensible expenses.

This is a joining of the unequivocal contraption, which after a short time demonstrates the centrality of adjusting the parts. In all constancy, in the setting of the adaptability in the application, the affiliation level is associated, with new potential couplings open. A loosening up of setup and of get together, that obliges creators the probability of complete package structures with fantastically cemented parts made execution on the last machine. The aware thought of the gearboxes licenses to see reducers in a pack easily mountable in a couple of minutes by any customer. A couple of packs are standard to all gearbox families, so they guarantee most unconventional flexibility to wholesalers and retailers who, even with an obliged piece of units, can structure the thing requested by customers with no inconvenience, with basic extra stores and in the improvement times.

Customization of worm and helical gearboxes

The Worm Gearboxes

The probability to re-endeavor the parts of worm plan reducers allows a redesign of their application. The worm gearboxes are changed naturally of the unequivocal materials chose forage.

The search for the most genuine technique revived the examination the potential results for each condition, getting striking flexibility the range and starting to streamline the usage of worm get ready reducers. The constituent parts of these things are on a particularly fundamental estimation three:

l The bundling,

l The worm shaft,

l The worm wheel.

It is this last part can offer the most unequivocal and pushed customizations to allow the reducer remarkable and variable applications. Clearly, obvious mixes are open on the crown, each really showed up in certain application settings. The crowns are contained two segments, in which the bronze can be used successfully where it is required:

The standard crown contains an assistance focus, routinely made of cast press, and a bronze cast, or the ring on which the toothing is made which pulls in the contraptions to work. All things considered, we gain customization of worm change reducers that can be used in a huge bit of the regular applications open.

The crown can be executed with a spheroidal cast-squash focus, an amalgam that performs better than the standard one, ideal for heavier applications, where unendingly essential quality is required. In any case, this composite is spun around strong oxidation and is as necessities be not sensible for the sustenance and sea/marine affiliations.

Crowns are made with the tempered steel focus point for the most touchy and eccentric present day applications, to keep up a vital separation from issues of utilization and deliberateness, for instance, oxidation.

Finally, it is possible to use supporting focus fixations in systematized or tempered steel in each and every other condition where a higher square is required and where the spheroidal cast iron cannot be used.

The potential delayed consequences of customization and change of the crown in like route interface with the bronze cast, the part that is balanced through the toothing structure to work and draw in the gearbox to work.

No comments:

Post a Comment